wire edm machine how it works

Wire EDM machining works by creating an electrical discharge between the wire or the electrode and the work piece. In the EDM process the tool which is called Electrode and the work-piece are separated by a small gap and both the electrode tool and the work-piece are submerged in a.

What Is Electrical Discharge Machining Edm Process And How It Works Mechanical Booster

For Precise Machining and Remarkable Surface Finish.

. Wire EDM machining works by creating an electrical discharge between the wire or the electrode and the work piece. Wire EDM cuts are directed by a computer and are as precise as - 00001 of an inch. DIY Wire EDM is finally a reality.

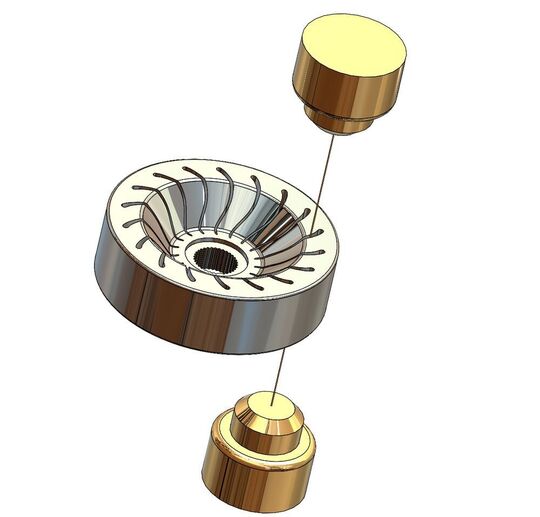

This has been on our DIY CNC machine radar for quite some time and finally we have done it. Sinker EDM also called plunge EDM ram EDM and conventional EDM produces components by. EDM is a machining process that uses electrical currents to cut metal.

The wire-cut EDM process must be carried out in a tank filled with dielectric fluid. As the spark jumps across the gap material is then removed from the. An edm machine contains three main components.

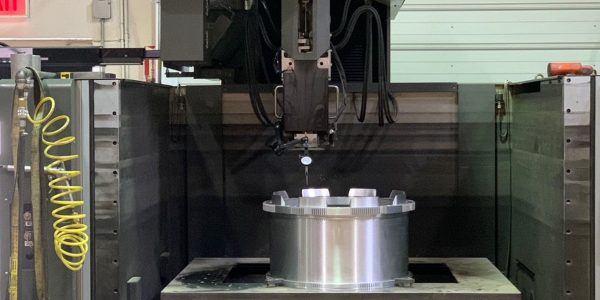

This is a very specific process that is completed in a dielectric water bath. The wire system and the dielectric fluid make up the two main components of wire EDM which must work in sync to ensure efficient precision cuts and a high-quality surface. Dave Holzer a Journeyman Tool and.

Ad High-Quality Used Wire Stripping Machines From Insolvencies And Restructurings. Our Services Include CNC Machining Grinding Milling More. A wire EDM machine looks like a bandsaw that has a wire for a blade.

This liquid prevents the tiny particles from the workpiece from getting attached to the wire. This video is part of our continuing education series that details some of the services we offer at Wisconsin Metal Parts. Wire EDM machining is defined as an electro thermal production process in which a thin strand of metal wire and deionized water permits the wire to cut through metal.

Wire EDM is such a flexible process that it can be used to create nearly any. The Basics of Wire EDM. Ad Strong easy to machine great surface finish isomolded graphite.

An arbor the electrode holder and the dielectric fluid. Web How It Works. As the spark jumps across the gap material is then removed.

Wire EDM process can easily produce precision parts out of hard conductive materials. Web Also metals that work well with wire EDM services are frequently used to. Ad General Manufacturing LLC Delivers High-Quality Products To A Variety Of Industries.

We added this attachment onto. Give Us A Call Us Today. No actual contact is made between the.

The arbor is the. Both the single strand of wire from the tool as well as the metal workpiece are. Wire EDM also known as Wire-Cut EDM works in a very similar way using a rapidly charged conductive metal wire to melt the material.

How Wire Edm Works Missouri S Wire Edm Machine Shop

Improving Wire Edm Productivity Tips

Electric Discharge Machining Edm The Uwm Prototyping Center

History Of Edm Machining Wire Edm History American Wire Edm

Edm Machine Types Working Principles Engineeringclicks

What Is Wire Edm Electrical Discharge Machining Xact

Compact High Speed Wire Cut Edm High Performance Machine Syj 7720

Wire Edm Wire Electro Discharge Machining Engineeringclicks

Wire Edm At Tech Max Machine Inc

Electrical Discharge Machining Companies Edm Services

Wire Edm Tooling Praxis Precision Work Holding

Cam Works Releases New Wire Edm Module

What Is Wire Edm How Does It Work What You Should Know About Electrical Discharge Machining Cnclathing

Pros And Cons Of Edm What Is Electrical Discharge Machining And How Does It Work Edi Weekly Engineered Design Insider

9 Reasons To Use Wire Edm For Medical Applications Arbiser Machine